Fourdrinier Tissue Machine

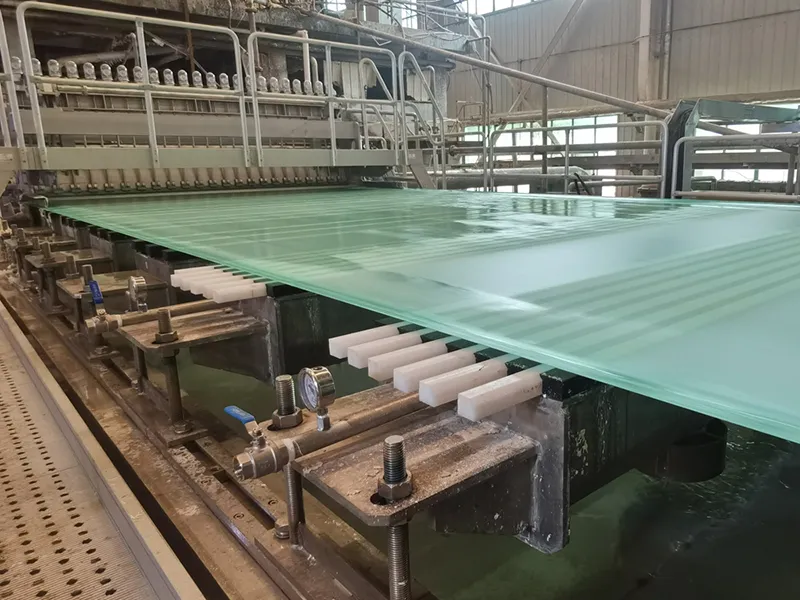

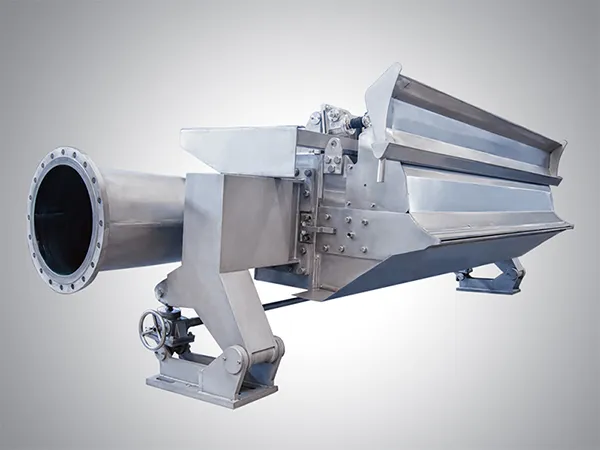

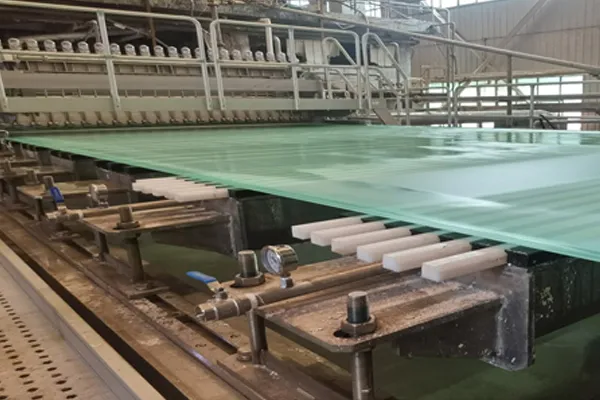

The primary configuration of the fourdrinier tissue machine comprises an air cushion headbox, fourdrinier former, Yankee dryer, Yankee hood, paper winder, etc.. This tissue making machine possesses significant advantages over the crescent former tissue machine in terms of its higher production rate of paper hand towels and kitchen paper.

| Paper Produced | Kitchen paper, tissue paper, paper hand towel |

| Raw Materials | Wood pulp, bamboo pulp, etc. |

| Trimmed Width | 1880-5600mm |

| Basis Weight | 19-45g/m² |

| Production Capacity | 10-115t/d |

| Gas Consumption | 1.9-2.2T (per ton of paper) |

| Energy Consumption | 280-380kW·h (per ton of paper) |

| Water Consumption | 4-6 m³ |

| Machine Speed | 200-1200m/min |

- The paper produced by this machine presents a consistent quality and uniformity, with minimal variations.

- Equipped with an efficient Yankee hood which exhibits an efficient steam consumption performance.

- The design of the forming section is not only user-friendly but also space-saving.

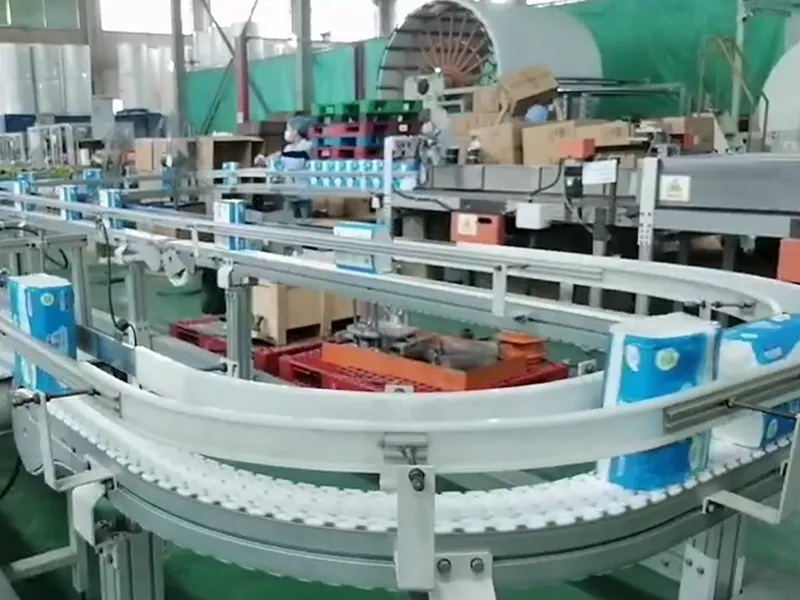

This paper machine is primarily used for the production of various paper types such as paper hand towels, kitchen paper, and thin sheet paper.

Standard Configurations: Former, dryer, paper winder, drive, pneumatic control

Optional Configurations

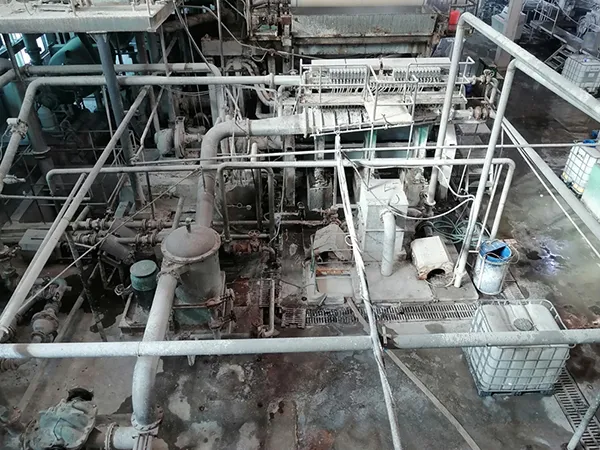

- Pulping equipment: pulper, refiner, desander, pressure screen, etc.

- Pulping control system: electric cabinet, electrical components, frequency conversion, control system

- Pipeline components in the pulping section: pipes, valves, fittings, etc.

- Paper machine auxiliary machinery: approach flow system, vacuum system, DCS control system, auxiliary electrical control

- Pipeline components in the paper making section: pipes, valves, fittings, etc.

- Post-processing equipment: rewinding machine, packaging machine, paper roll processing equipment, tissue paper processing equipment

- Spare parts: guide rollers, vacuum rolls, paper roll shaft, etc.

Our expert team works together with you according to your specific needs.

-

Case Study

Case StudyBefore this project, our operations were centered around an inclined wire paper machine, and our major concern was to improve product quality as well as reduce production costs through an update. During our technical discussions with the Bingzhi Machinery team, their detailed process analyses enabled us to maximize the utilization of existing components, thereby reducing the cost of retrofitting. After the retrofitting was completed, we were able to produce products that exceeded our quality expectations achieving our set goals. The product quality has significantly improved, and using the new hood and complete hot air system has increased the operating speed alongside a decrease in both steam and power consumption. This technical transformation was highly successful.