Our company is not just a supplier, we are a partner in innovation for the pulp and paper industry. We offer a wide range of paper manufacturing machines and essential components, tailored to meet the diverse needs of our clients.

Our tissue making technology ensures the sustainable production of high-quality paper products, ranging from everyday household tissues to specialty papers. But our service portfolio does not only cover supplying machinery, but also consists of providing customer-centric solutions with product-enhancing and strategic machine retrofitting services. With our extensive experience, we support your needs for a new paper project in its initial phase of planning and installation to comprehensive training, as well as revitalizing an existing one for its optimum use over the years.

Our company offers a comprehensive range of turnkey solutions for paper mills, ensuring a smooth and worry-free experience for clients throughout the entire project lifecycle. Our services encompass paper and tissue industry project planning, design, equipment procurement, installation and commissioning, production operation, and after-sales maintenance.

More Turnkey SolutionsWhether you're operating a new or established paper mill, the ultimate goal is to maximize reliability and optimize performance.

Paper machine retrofitting is an effective approach to address production technology bottlenecks, reduce costs, enhance safety, and improve energy efficiency.

We tailor our approach to meet the unique needs of each paper plant project, considering the distinct factors specific to every client. By doing so, we deliver effective strategies that enable our clients to achieve their business objectives.

Our key target clients include:

1. Domestic and international paper manufacturing companies, as well as investors seeking to venture into this industry

2. Paper manufacturing companies in need of technological upgrades or retrofitting

We're here to facilitate seamless operations and empower your business to achieve its operational goals effectively and efficiently.

Our expert team works together with you according to your specific needs.

The crescent former tissue machine is a sophisticated piece of equipment, comprising several key components...

The primary configuration of the fourdrinier tissue machine comprises an air-padded headbox, fourdrinier former, Yankee dryer, Yankee hood, paper winder, etc..

The TAD (Through Air Drying) paper machine employs a non-compressive drying technology that utilizes hot and dry air.

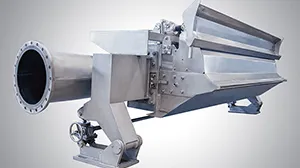

Headboxes play a crucial role in paper machinery, offering efficient and reliable performance to meet various production requirements.