Paper machine solutions for

Medical filter paper and glass fiber paper part of the specialty paper category, characterized by high porosity and air permeability, as well as their high filtration efficiency, heat resistance, and corrosion resistance, making them ideal for effectively filtering tiny particles. They are widely used in chemical, pharmaceutical, food, environmental protection firm, and other industries.

The specialty paper produced by our Inclined wire paper machine has uniform basis weight, good air permeability, and excellent porosity. Its physical properties and filtration material performance are at the forefront of the industry, making it the ideal choice for customers seeking high-quality products.

Our team is prepared to support you from the initial design phase through to the comprehensive turn-key service with paper machines to produce filter paper and fiberglass paper.

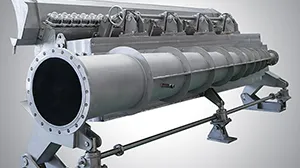

The inclined wire paper machine is utilized for the production of specialty paper. It features a dense wire configuration and is capable of processing longer fiber lengths. This enhances dehydration performance and results in better uniformity of the manufactured paper. The wire forming section's angle of inclination is adjustable between 0° and 30°. This specialty paper machine can achieve a maximum paper production rate of up to 1300g/m².

For paper manufacturing clients, paper machine components play an essential role to enhance paper productivity, optimize product quality, reduce energy consumption, and improve the working environment. The utilization of primary components such as headboxes, Yankee hoods, dust filters, pulp stock mixers, and post-processing equipment are vital in enabling paper mills to achieve automated and efficient production processes, ultimately enhancing their competitiveness and market presence in paper industry.

Our expert team works together with you according to your specific needs.