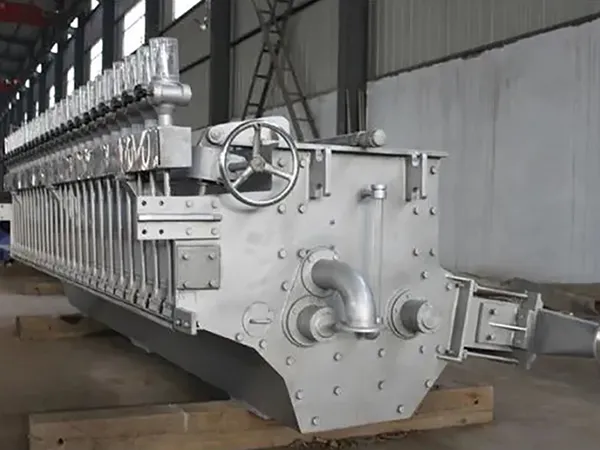

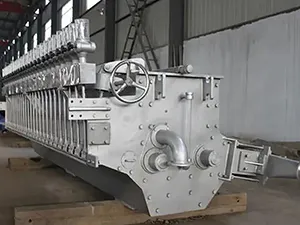

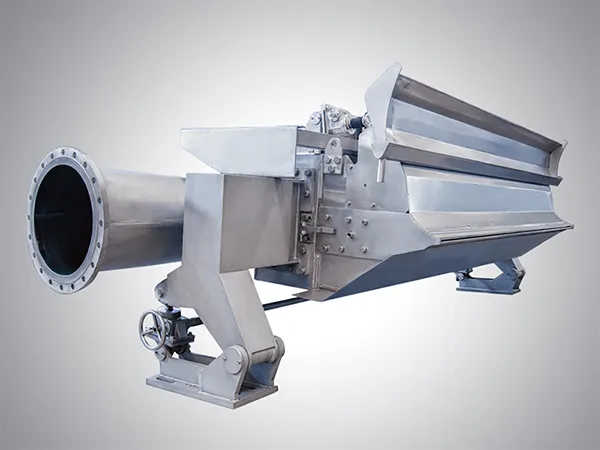

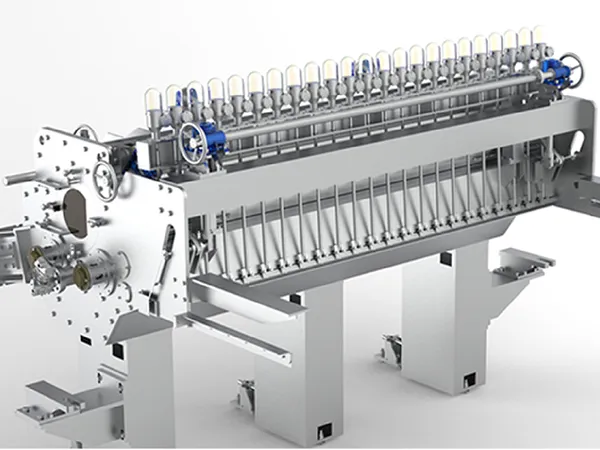

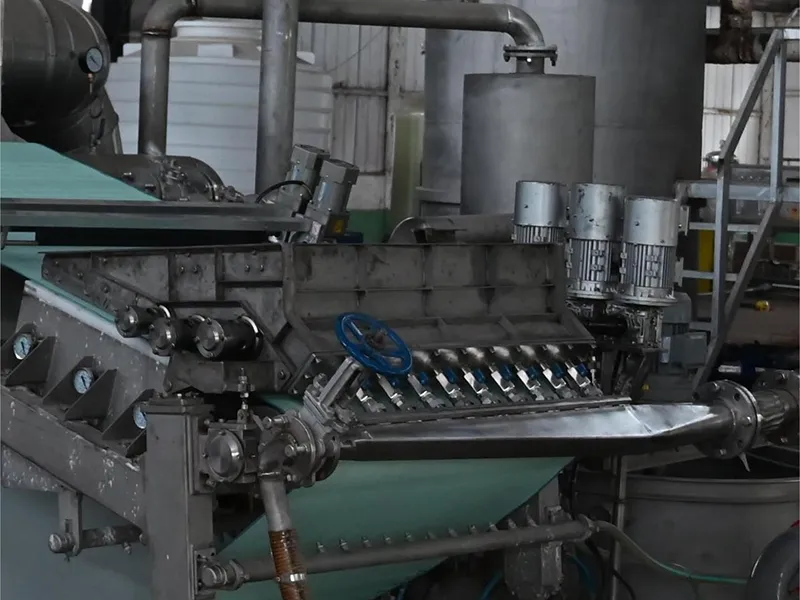

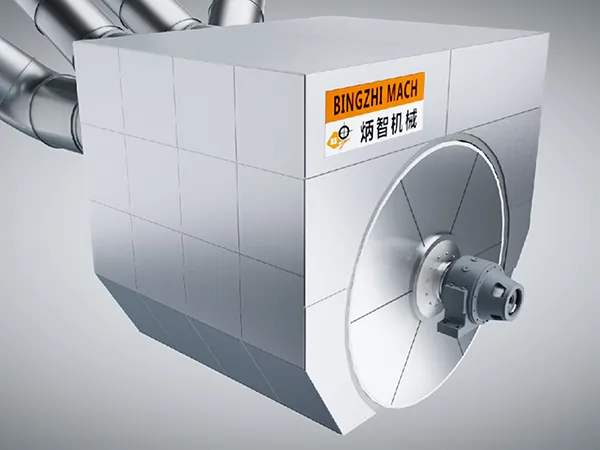

Open Headbox

The headbox is composed of a stock header pipe, consistency control device, lip board, and box body. The consistency control device consists of two holy rolls with varying opening rates, while the spray lip comprises an adjustable upper lip board and a fixed lower lip board. A small lip board is attached to the lip edge, and its adjustment is carried out using a worm gearbox for precise calibration and effortless customization. The upper lip board can be fully opened, facilitating ease of cleaning and maintenance.

Open headbox has been specifically crafted for low-speed fourdrinier paper machines with speeds below 250 m/min.

| Working Width | 1880-5600mm |

| Headbox Pond Width | 1880-5600mm |

| Working Speed | 100-250m/min |

| Consistency | 0.1-2.5% |

| Max. Recirculation Flow | 10-15% |

- The inlet pipe has been designed in a conical isobaric configuration, which effectively guarantees a consistent and stable pressure distribution throughout the nozzle.

- The opening rate and rotational speed of the holy rolls are determined based on the properties and concentration of the stock to ensure thorough mixing of the pulp.

- Constructed from 304 stainless steel, the headbox’s body and its surfaces in contact with stock are electropolished to a mirror finish to prevent pulp adhesion and minimize scaling.

- Open headbox can be equipped with a water dilution unit to achieve adjustable cross-sectional basis weight.

-

Fourdrinier Tissue Machine

This paper machine is primarily used for the production of various paper types such as paper hand towels, kitchen paper, and thin sheet paper.

-

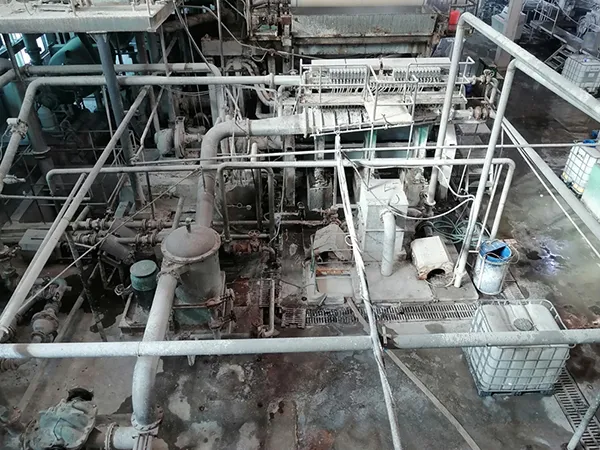

Machine Retrofitting

Paper machine retrofitting is an effective approach to address production technology bottlenecks.