Shaanxi Bingzhi Machinery Co., Ltd. was established in 2013 and is a company dedicated to providing customized papermaking solutions for paper enterprises. Our products mainly include a vast variety of paper making machines such as crescent- former tissue machines, fourdrinier tissue machines, inclined wire paper machines, and related equipment such as multiple types of headbox, Yankee hoods, dust filters, and more.

We collaborate with several domestic universities, incorporating the latest research findings into our product development. We continuously update our products and make improvements based on the vast enhancement of paper making industry. By analyzing the issues encountered in the usage of machine, we optimize the mechanical structure and process flow of our products to ensure its optimal performance. Therefore, our professional technical team is capable of providing customers with a complete turnkey solution, including plant design and planning, infrastructure evaluation, process flow, equipment supply, installation and commissioning, start-up operation, personnel training, on-site problem-solving, and overall project management.

We support our clients throughout the entire lifecycle of paper mill, from initial investment to the conclusion of its operational life. We provide our expertise, knowledge and devices to empower you to excel in the evolving world of pulp and paper industry.

Since our establishment, we have supplied over 50 machines to numerous paper enterprises in China and abroad. Our paper making machines have been exported to countries such as South Africa, Venezuela, Myanmar, Colombia, and have received high recognition from our customers.

Our manufacturing capabilities are supported by a wide range of advanced machinery. This includes high precision machine tools such as GTXK20E-4 CNC gantry milling machine, CS6140 lathe for precision work, and Z3050×16/1 radial drilling machine for robust drilling operations. We also use LM-10Y series fully automatic vibration aging equipment to improve the durability of our products. Additionally, our facility is equipped with various welding and cutting technologies including CO2 welding, argon arc welding, laser welding, and plasma arc cutting. To support diverse mechanical processing needs, we have wire-cutting EDM machines, electric threading machines, round pipe bending machines, plate rolling machines, shearing machines, and bending machines. These tools allow us to maintain high precision and quality in our manufacturing processes.

The company was established in 2013. The team of professionals independently funded the upgrade and retrofitting of the first low-speed cylinder paper machine to a 400m/min crescent former paper machine, which was successful and deepened our understanding of the crescent former paper machine.

In 2015, based on the experimental machine test data, our first generation of completely self-developed and manufactured 700m/min crescent former paper machine successfully carried out its first paper production, which propelled the rapid development of crescent former paper machines in domestic market.

In the subsequent development process, we continuously improved the process flow, site installation, production operation, operational management, and addressed issues identified during maintenance. We carried out updates and iterations on the paper machine. After 10 years of uninterrupted research and innovation, our company is now capable of designing and manufacturing a Crescent former paper machine with a width of 5600mm and a speed of 1800m/min. The energy consumption per ton of paper produced can be as low as 1.9-2.2 tons of steam and 280-380kW•h of electricity, which demonstrates significant energy-saving advantages compared to similar products in the market.

Our expert team works together with you according to your specific needs.

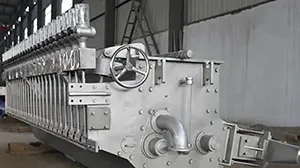

The primary configuration of the fourdrinier tissue machine comprises an air-padded headbox, fourdrinier former, Yankee dryer, Yankee hood, paper winder, etc..

The TAD (Through Air Drying) paper machine employs a non-compressive drying technology that utilizes hot and dry air.

The inclined wire paper machine is utilized for the production of specialty paper.

The headbox is composed of a stock header pipe, consistency control device, lip board, and box body.