The toilet paper making machine's hot air system often experiences high humidity and dust, leading to the gradual blockage of heating elements. This blockage can significantly affect ventilation and heat, resulting in reduced hot air efficiency and increased production costs. Our company has recently designed and developed a fully automatic dust filtration device that efficiently filters out a considerable amount of dust which is present in the hot air during the normal operation of the paper making machine. This ensures the ventilation and heating efficiency of the hood, thereby enhancing the overall performance of the paper making machine.

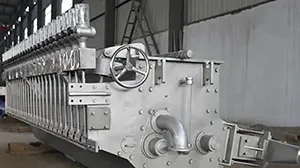

The primary configuration of the fourdrinier tissue machine comprises an air-padded headbox, fourdrinier former, Yankee dryer, Yankee hood, paper winder, etc..

The TAD (Through Air Drying) paper machine employs a non-compressive drying technology that utilizes hot and dry air.

The inclined wire paper machine is utilized for the production of specialty paper.

The headbox is composed of a stock header pipe, consistency control device, lip board, and box body.